Selecting the right fastener material from the vast array of those available can be a daunting task. Functions as needed throughout its intended life cycle.

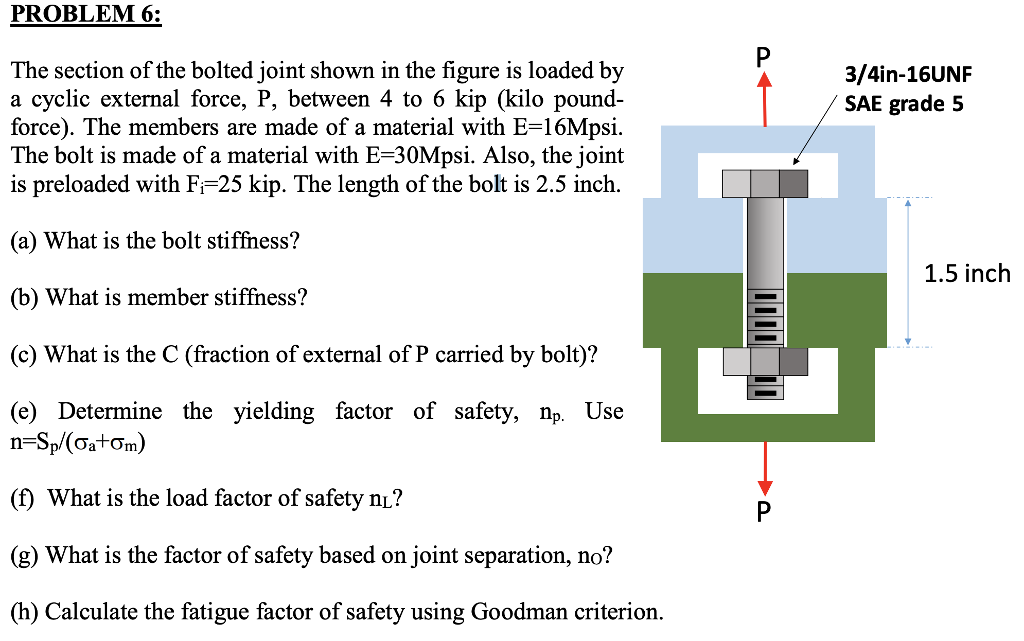

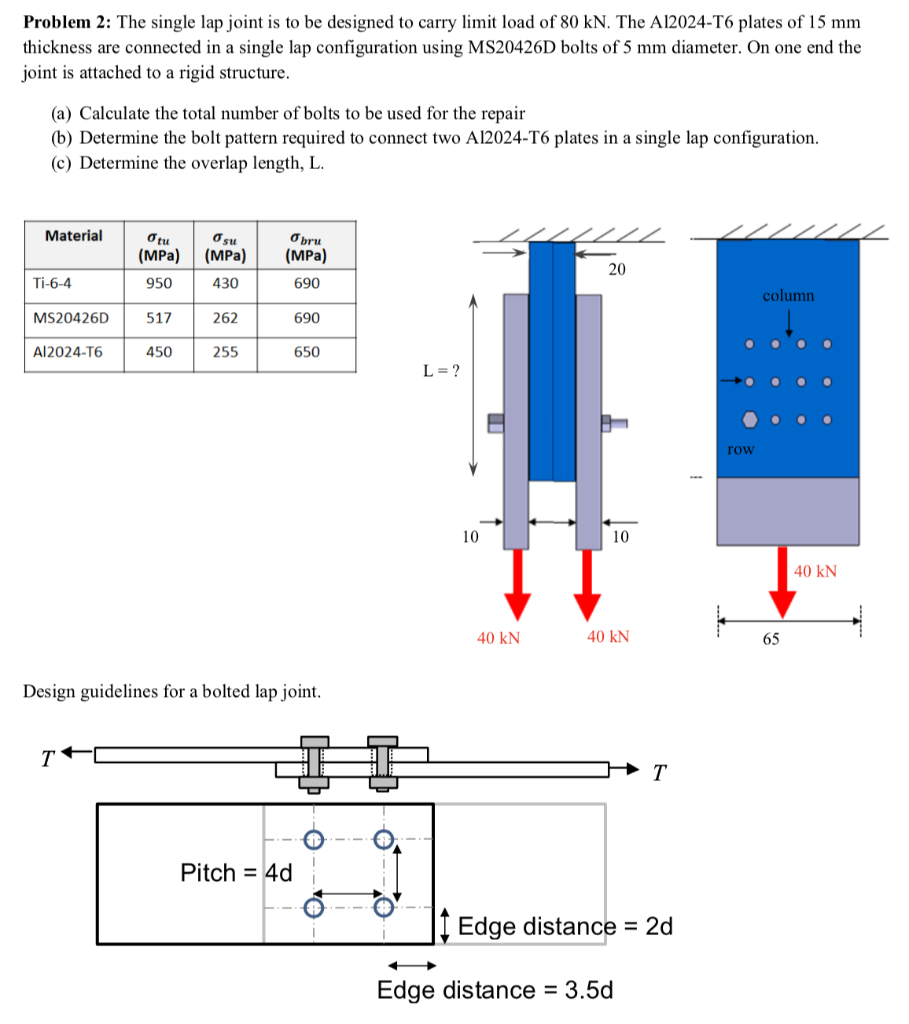

Solved Problem 6 The Section Of The Bolted Joint Shown I

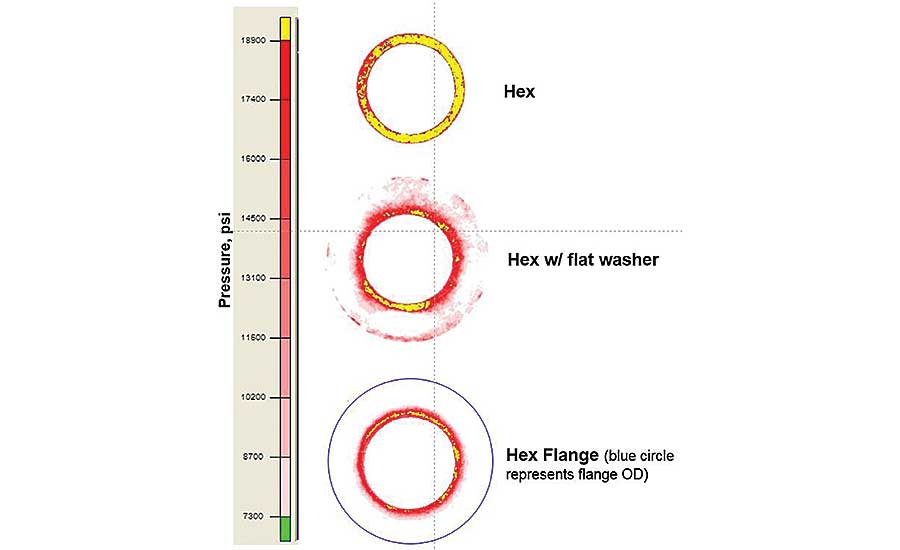

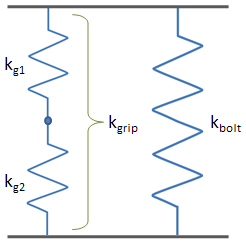

Analyzing Bolted Joints For Clamp Load And Joint Stress 2017 04

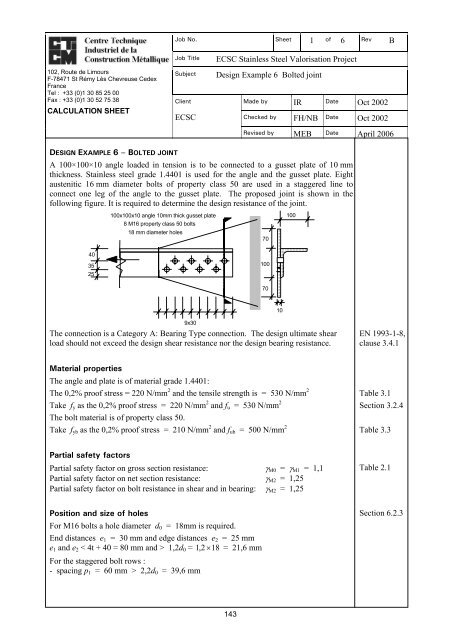

Bolted Joint Steel Stainless Org

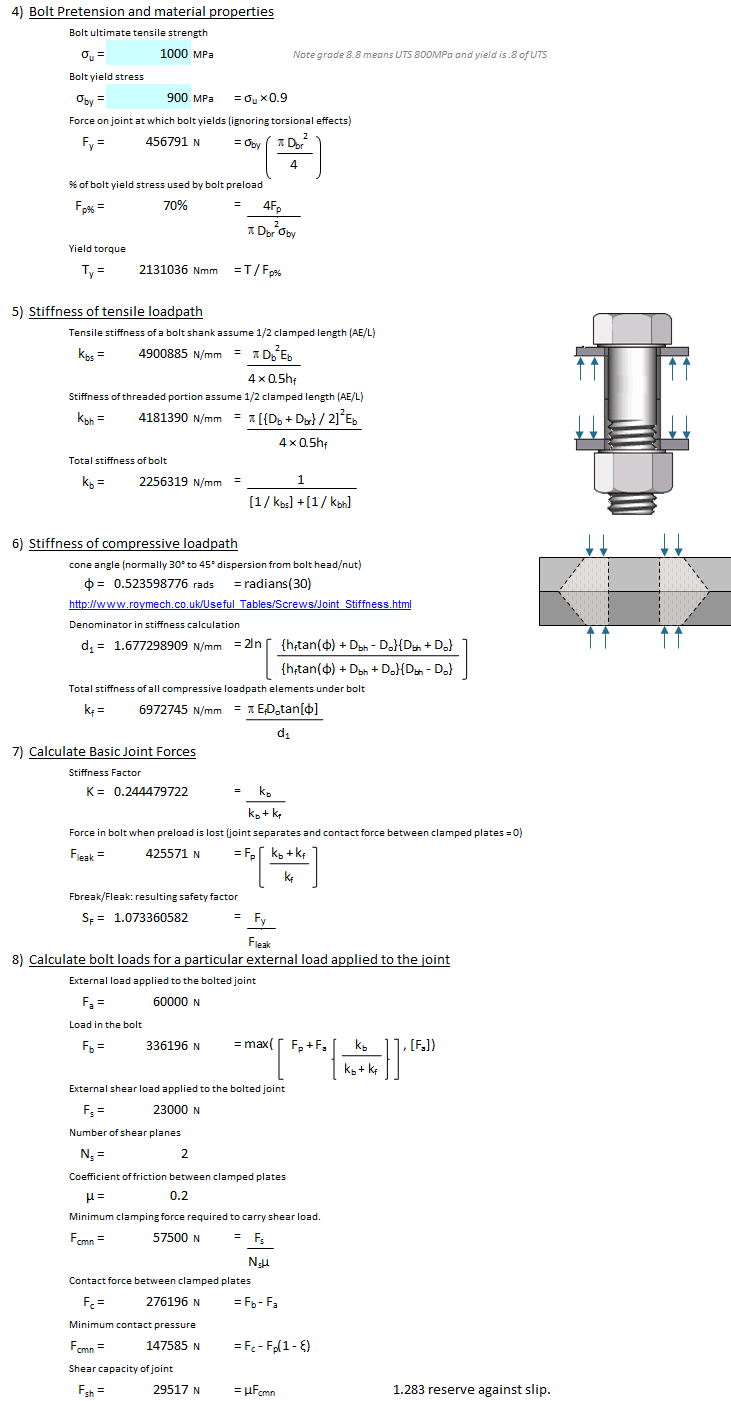

See the reference section for details on the methodology and the equations used.

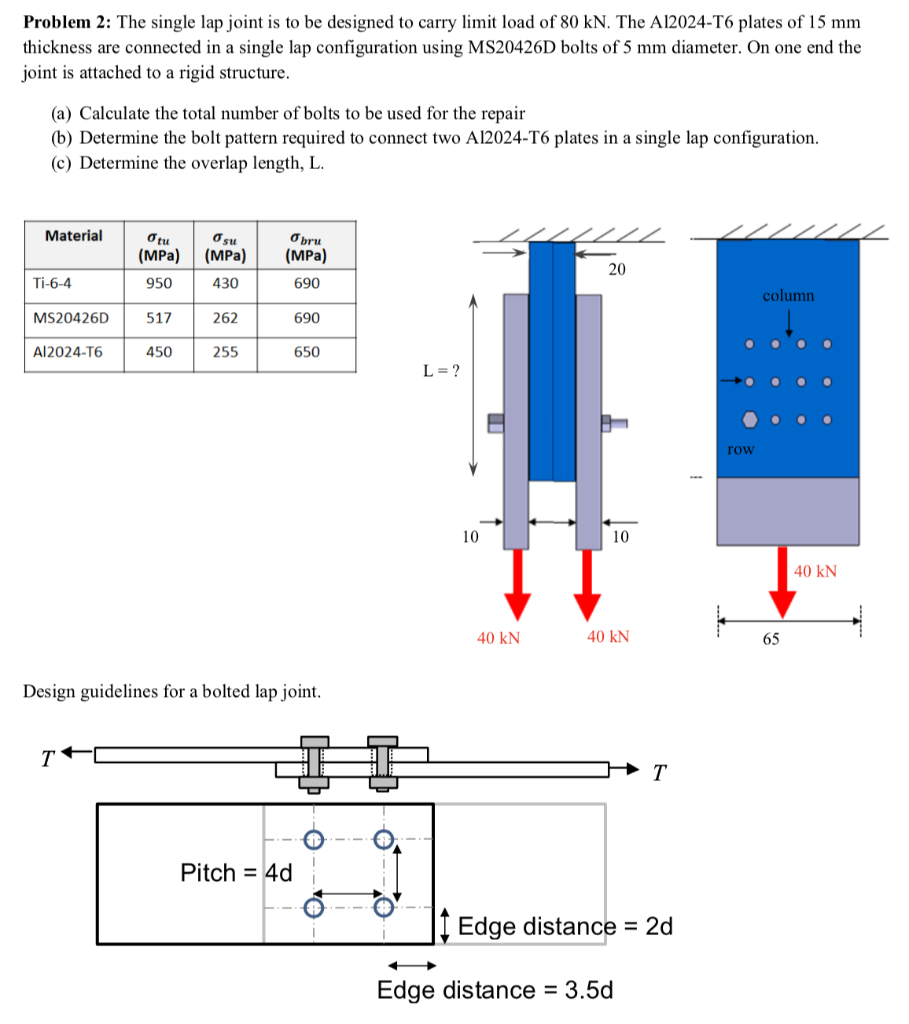

Bolted joint design calculations.

Quantify requirements and identify design considerations for the joint.

Bolted joint design calculation example for joint in tension properly designed bolted joint is extremely important for striking the balance between the cost and life of the joint.

Axial loads shear loads thermal loads and thread tear out are used in factor of safety calculations.

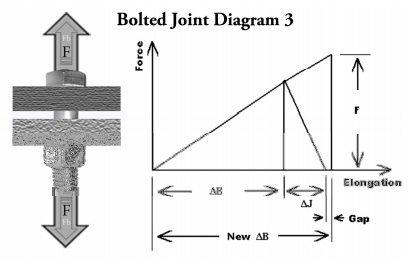

Guidance is provided for general bolted joint design computation of preload uncertainty and preload loss and the calculation of the bolted joint factor of safety.

Life cycle environments design loads loading cycles temperatures stiffness allowable permanent deformation design criteria cost lead time ease of assembly schedule needed goal.

Bolted joint design there is no one fastener material that is right for every environment.

They consist of fasteners that capture and join other parts and are secured with the mating of screw threads.

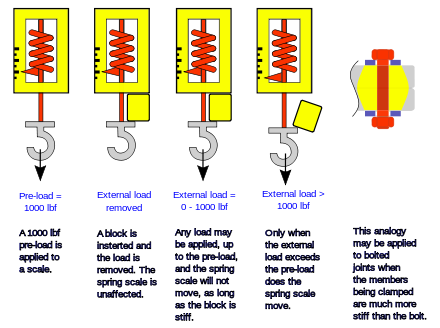

Bolted joints are often tightened to 75 to 80 of bolt proof load.

Guidance is provided for general bolted joint design computation of preload uncertainty and preload loss and the calculation of the bolted joint factor of safety.

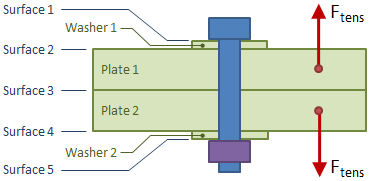

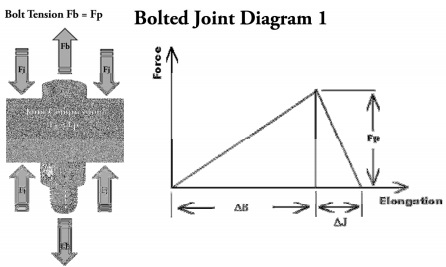

The bolted joint works by inducing an initial clamping force preload on the joint by threading the fastener into either a nut or into threads that have been tapped into one of the parts.

This preload ensures that the clamped parts remain in contact and in compression throughout the life of the joint.

As a design engineer for a good bolted joint design for a given loading conditions and materials of the abutments you have to basically select the following design parameters.

There are two main types of bolted joint designs.

Bolted joints are one of the most common elements in construction and machine design.

An overview of the current methods used to analyze bolted joint connections is given.

Several methods for the design and analysis of bolted joint connections are presented.

A joint that.

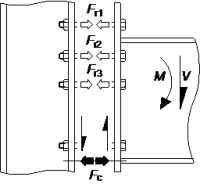

Force calculations for bolted joints.

Careful consideration must be given to strength temperature corrosion vibration fatigue and many other variables.

By combining the torque angle curves with a few simple calculations and a basic understanding of the engineering mechanics of threaded fasteners you can obtain the practical information needed to evaluate.

See the instructions within the documentation for more details on performing this analysis.

In the tension joint the bolt and clamped components of the joint are designed to transfer an applied tension load through the joint by way of the clamped components by the design of a proper balance of joint and bolt s.

The bolted joint analysis calculator allows for stress analysis of a bolted joint accounting for preload applied axial load and applied shear load.

Tension joints and shear joints.

Sr1 Bolt Calculation To Vdi 2230

Https Prod Ng Sandia Gov Techlib Noauth Access Control Cgi 2008 080371 Pdf

Screws Fasteners And The Design Of Nonpermanent Joints Ppt

Bolted Joints Youtube

Calculation Of Bolt Torque For Flanged Joint Assembly

Bolted Joints An Overview Sciencedirect Topics

Gaskets Basics Types Working Principle Calculation Of Bolt

Moment Resisting Connections Steelconstruction Info

Prestressed Bolt Connection

Http Nutek Us Com Qitt06 20 20bolted 20joints Pdf

Bolted Connections In Eurocode 3 1 Hello Life

Analyzing Bolted Joints For Clamp Load And Joint Stress 2017 04

Bolted Joint Analysis Mechanicalc

Sr1 Bolt Calculation To Vdi 2230

Bolted Joint Design Fastenal

Bolted Joint Design Calculations Batan Vtngcf Org

Pion Www Gopion Com

Bolted Joint Design Calculations Kaser Vtngcf Org

Bolted Joints Theory And Design Problems

Bolted Joint Design Fastenal

What S The Difference Between Bearing Shear And Tear Out Stress

How To Calculate Bolt Value Design Strength Of Bolt Is 800 2007

Bolted Joint Analysis Mechanicalc

Bolted Joint Design Calculations Kaser Vtngcf Org

How To Calculate Maximum Fastener And Screw Torque Omnia Mfg

Bolted Joint Wikipedia

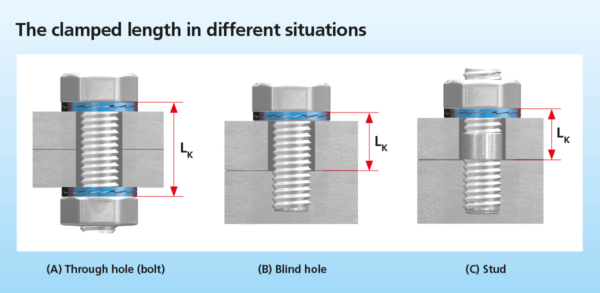

Optimizing A Bolted Joint Through Clamped Length Nord Lock Group

Lightning Bolt Design

19 Rough Estimation Of Bolted Joints According To Vdi 2230 Sheet 1

Hexagon Info Letter No 135

Bolted Joint Wikipedia

Detailed Bolted Joint Calculations Xls

Find Avg Bolt Shear Stress Of Lap Joint And Butt Joint Strength

Lecture 2 Prob3 Bearing Stress In Washer And Bolt Youtube

Bolted Joint Design Fastenal

0 Yorumlar